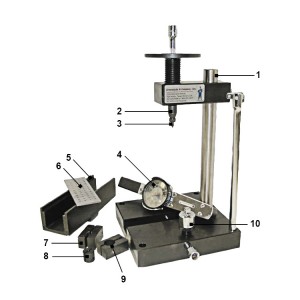

STF-250

Tapping Screws are widely used fasteners in high volume assembly applications. Tapping screws must be tested for ductility, torsional strength, drive test, drive torque, drill-drive time, and hydrogen embrittlement. These requirements may vary depending on the screw types. The screw testing fixture, STF 250, along with the following equipment required to conduct these tests are provided by Greenslade.

- Screw Testing Fixture, STF-250

- Driver bit holder, STF BIT HOLDER

- Driver bits (specify recess type and size)

- Torque wrench (specify smallest and largest screw to test)

- Test plate holder, STF-TPH 200

- Test plate (specify screw type and size to test)

- Split collet for testing screws smaller than 1/4 inch and M6 and larger

- Split collet for testing screws smaller than 1/4 inch and M6

- Split collet holder for small screw collets, STFCH 250

- Ratchet adaptor to facilitate rapid screw testing. STF RATCHET